- No products in the cart.

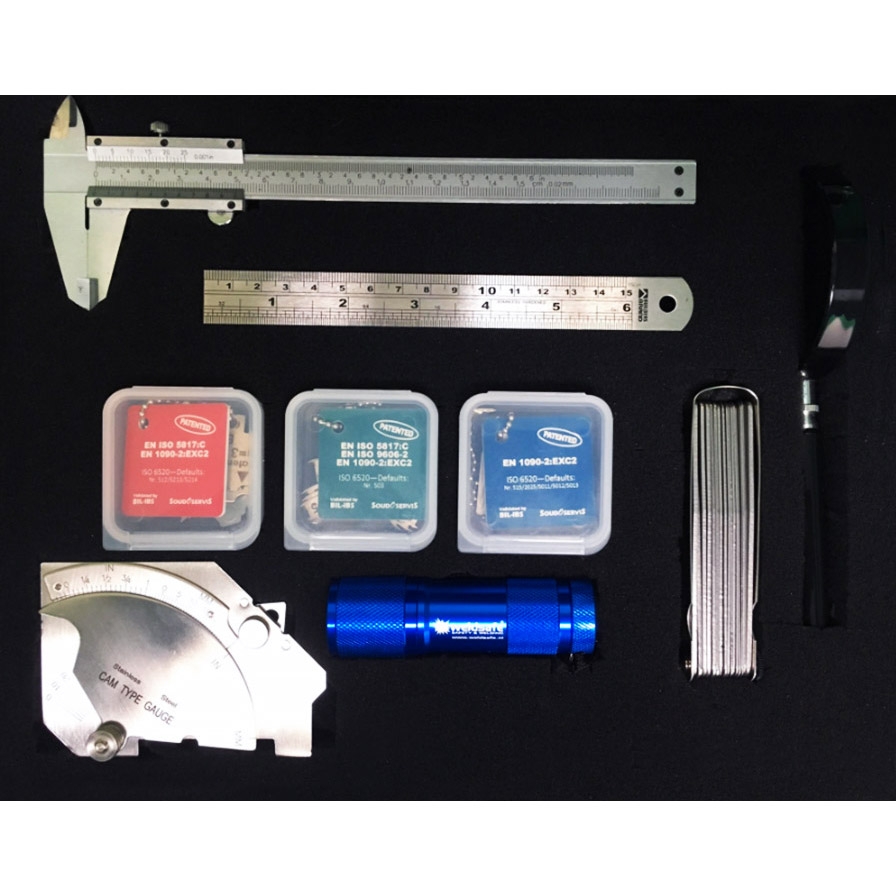

Complete VT® case

€578,05 (HT)

Description

Case including all necessary equipment for visual inspection with the new VT® gauge concept. Suitable for all types of assemblies. Ideal for quality managers, inspectors, examiners, welding coordinators, engineers, or qualified welders. The case will be adapted according to the standard to be applied: ISO 5817; EN 1090-2; ISO 9606-1.

Composition of the basic kit:

- VT®TOTAL KIT

- Vernier caliper ref. 98.000.501

- 15cm steel ruler ref. 98.000.515

- Magnifying glass ref. 98.000.901

- Thickness gauge ref. 98.000.520

- Flashlight ref. 15.000.244710110

- Measuring gauge ref. 98.000.105

Additional information

| Standard | EN1090-2:EXC1, EN1090-2:EXC3, EN1090-2:EXC4, ISO 5817:B, ISO 5817:C, ISO 5817:D, ISO 9606-1 |

|---|---|

| Archives des %%term_title%% %%page%% %%sep%% %%sitename%% | Engineer, Examiner, Inspector, Quality manager, Welder, Welding coordinator |

| Imperfections |

Guy Lardinois SPRL Company

VT© gauges provide significant benefits for welders by reducing training needs. The approach is highly practical and easy to comprehend. The gauges offer excellent value-addition to welding processes. It is a precise and efficient solution.

There's no need to comply with elaborate standards or conduct complex calculations for visual weld quality control. For instance, for craters, visual inspection is now immediately possible without any calculations. The VT© gauge and a flashlight are all that is required to handle any welding situation. By saving an enormous amount of time and ensuring precision, VT© gauges provide a valuable addition to the welder's toolkit. Training requirements are minimized. The approach is highly pragmatic, and it is straightforward to determine the appropriate gauge with the help of available visual aids.